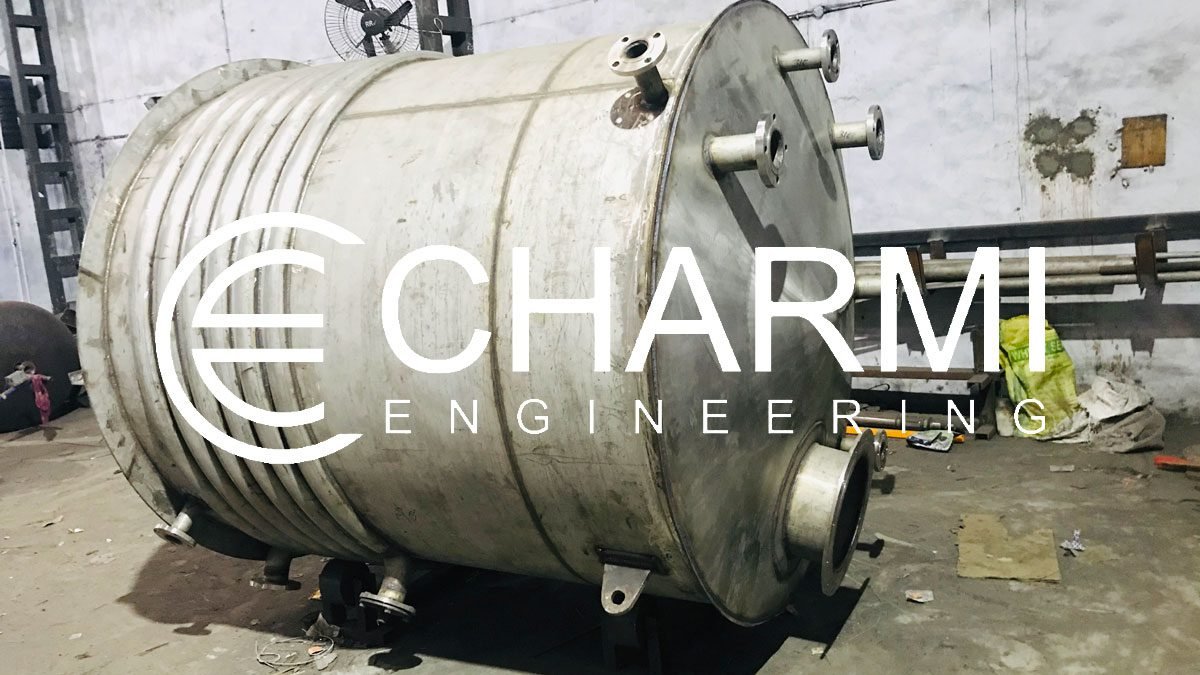

Double Jacketed Reactor

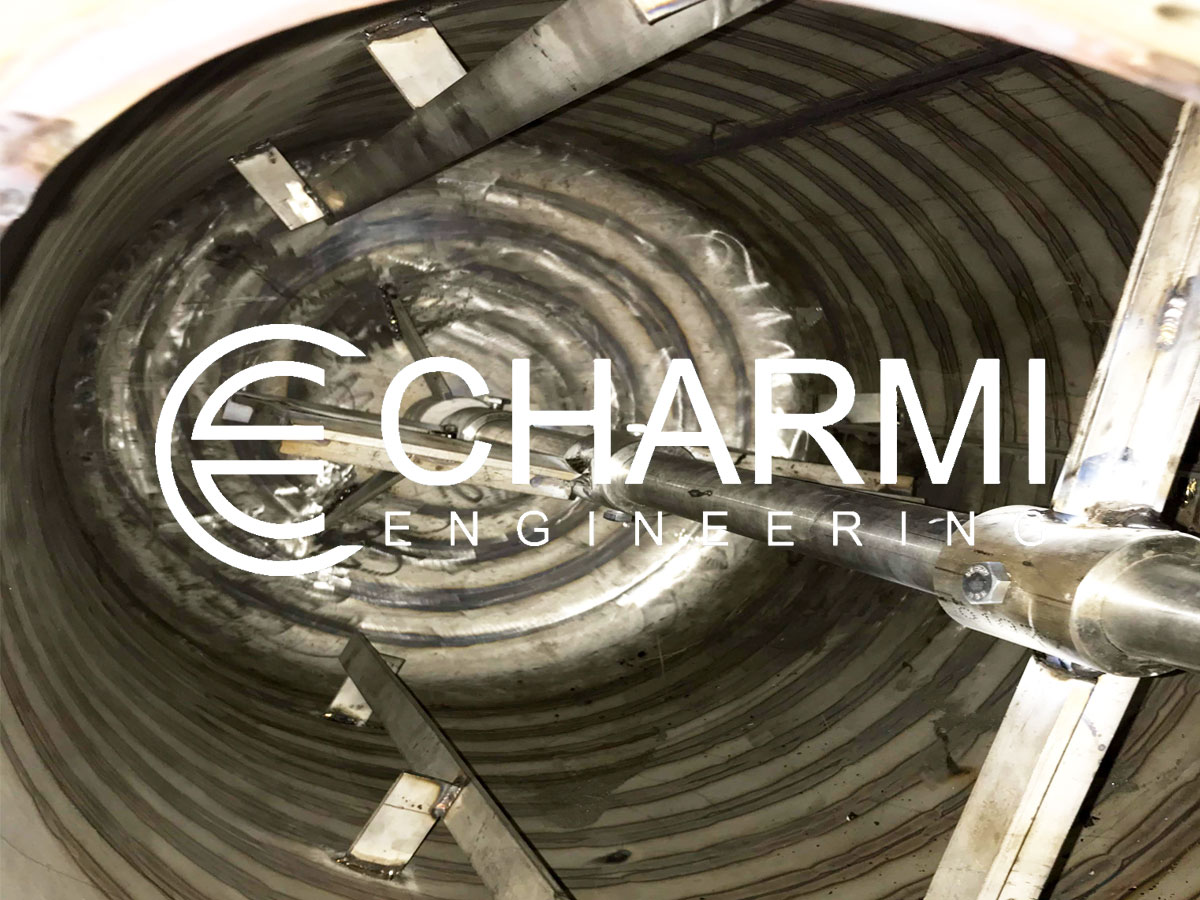

Charmi Engineering is are one of the leading manufacturer, supplier & Exporter of Reactor vessels and Jacked Vessel of capacities varying from 100 Liter to 50,000L in various materials of constructions such as stainless steels Gr. 304 /Gr. 304 l / Gr.316 / Gr.316 l/Mild Steel etc. Jacketed reactor vessels are mostly used in different sector such as Pharmaceutical plant, chemical plant, dye plant adhesive plant , cosmetic, etc. In jacketed reactor, a jacketed welded on the shell to provide steam, Thermic Fluid or hot water . This jacket can be made of mild steel or Stainless Steel as per the application of the use. In jacketed Vessel there are two types of jacket single stage and double stage. A stiffener is welded on shell to withstand the pressure developed in the jacket and it also helps in proper distribution of steam and oil. Top side provide you motor and gear box for agitation purpose , agitator blade is different as per requirement like anchor , flat blade , twisted blade , high speed also we can do .in double jacket one jacket for steam ,Thermic Fluid Heater, Hot water and second jacket is insulation jacket , insulation jacket made by aluminum ,Stainless steel and mild steel as per client requirement .

- Jacket use for heating and cooling both purpose

- Jacket material mild steel and Stainless steel

- Jacket we provide 60 % to 90 % of vessel as per Requirement

- Insulation Jacket use for heating loss and cooling lose recover

- Insulation material is Rockwool , glass wool

- Temperatures range of jacketed reactor is 50 degree to 30 degree

- In vacuum provide mechanical seal or Glan & Pushar Assembly

- Jacket have some pressure that way we provide safety valve and pressure gauge

Applications

- Pharmaceutical industry

- Chemical industry

- Food and beverages industry

- Petro-chemical industry

- Resins industry

- Polymers industry

- Coatings industry

- Adhesives industry

- Agricultural industry

- General chemicals industry

- Plastics industry

- Rubber industry

Features

- Easy in use

- Less maintenance

- Cost effective

- Maintenance & Trouble Free Performance

- High accuracy

- Superb tensile strength

- Unsurpassed performance